Tetra locomotion¶

Introduction¶

A tetra design is composed with 2 motors, each driving two wheels. The motors have a pinion that drives two gears attached to the wheels.

Both the pinion and the gear must have the same module. There is a simple equation that relates the module, the number of teeth and the reference diameter of the gear:

When working with gears there are 3 different diameter that we could refer to: the internal, the reference and the external diameters.

The external diameter can be calculated with:

The resulting locomotion in a tetra design looks like this:

Restrictions¶

Note we have two important restrictions:

- The wheel must have a diameter greater than the external gear diameter \(D_e^{gear}\). Otherwise the gear would be in contact with the floor.

- The wheel must have a diameter smaller than the reference diameter of the gear plus the reference diameter of the pinion \(D_r^{gear} + D_r^{pinion}\). Otherwise the two wheels would be in contact with eachother.

- We will usually want to keep some space between the floor and the base of the robot (i.e.: the PCB).

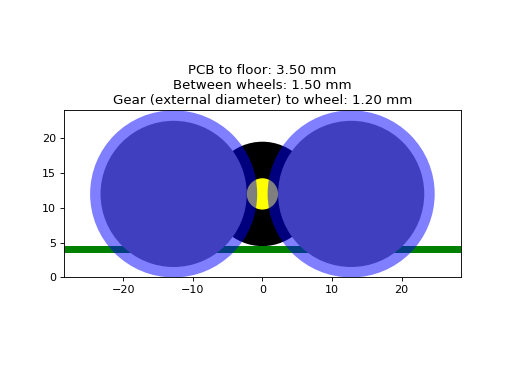

In some cases, keeping that space between the floor and the PCB is not a problem:

(Source code, png, hires.png, pdf)

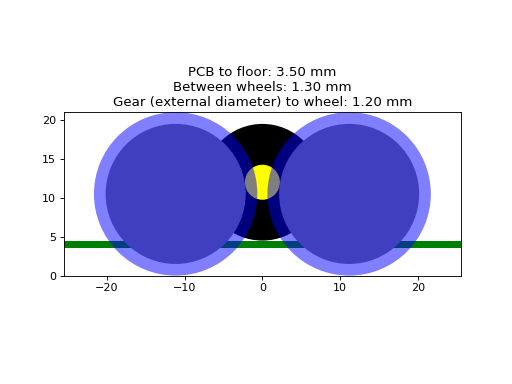

If the configuration leaves too little space between the PCB and the floor then we can always shift the motor a bit up:

(Source code, png, hires.png, pdf)

Note

Shifting the motor up will shift the center of mass of the robot a bit up as well. It will also compesate worse the forces generated because of the contact between the gears, although this might have a very little impact overall.

Of course, another alternative is to cut the base/PCB to allow the motor to pass through it. As a downside, cutting the PCB might not be easy and might not left much area connecting the front and the back parts of the robot.